Synchroline

Fully servo motor flexo press

Product overview

Ever since its introduction to the market, Synchroline has redefined the future of the printing industry. Its cutting-edge technology based on servo motors and sophisticated software developments make Synchroline the benchmark for innovation in printing. Its slogan, "Label the Future," represents not just a motto but a mission.

With Synchroline, "Label the Future" means looking beyond current limitations and embracing the unlimited potential of printing. With this revolutionary machine, every project becomes an opportunity to explore new horizons in label and packaging production. Thanks to its versatility, Synchroline can print on a wide range of substrates, including BOPP, PVC, PE, PET, paper, adhesive paper, thermal paper, cardboard, laminated materials, and much more.

Synchroline's advanced automation minimizes operator efforts, ensuring the highest quality in the flexographic process. With Synchroline, every step of production becomes more efficient and precise.

But Synchroline is much more than that: it's a fully modular in-line flexographic machine that can be tailored to meet specific production needs. From multi-layer units to hot foiling, from screen printing to cold foil application, and more, Synchroline offers a wide range of options to customize the printing process.

In short, Synchroline is the printing freedom machine. Every label that passes through Synchroline is a blank canvas ready for art and innovation. Label the Future with Synchroline means inspiring the world with your creativity and redefining what is possible in label and packaging production. Synchroline is the innovation driving the printing industry forward, opening new opportunities and enabling businesses to stand out uniquely in the market.

Main features

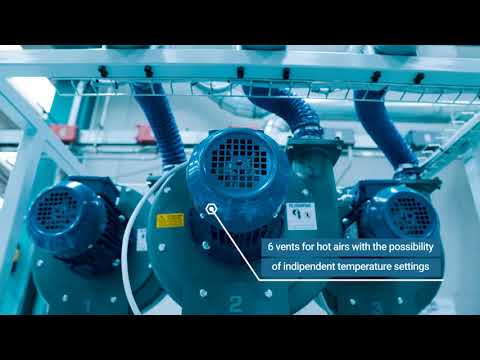

SYNCHROLINE is equipped with A.B.S. printing unit:

- Hi-FiT system: An innovative system is used for print rolls allowing for immediate fitting of cylinders of different diameter with no need for an adapter. In fact print rolls lay on a special algorithmical-studied curve that ables to keep constant the printing pressure varying the roll diameter.

- Hi-FiX system: The plate cylinder is pneumatically clamped with a conical piston that grants irreversibility of motion and reduces motions and vibrations to a minimum.

- Hi-DynamiX system: The blade is pressured against the anilox roller with pneumatical system, determining an auto-adaptive pressure dynamic, resulting in the best ink distribution.

- Hi-InX system: When the machine stops, the ink roller (anilox) is first removed, followed (after a settable time) by the print cylinder, in order to clean ink in excess (an essential operation when using non-UV inks).

FOREFRONT ELECTRONCS:

- Fully automatic electronic pre-registration system: minimum material waste, minimum waste of time, maximum precision.

- Fully automatic register controls with parametrizaion system for perfect registration on extensible materials.

- Electronical tension control for perfect tensioning of different substrates.

- Quality analisys sytem.

Tech Specs

| Technical Data | SYNCHROLINE 330 | SYNCHROLINE 430 | SYNCHROLINE 530 | SYNCHROLINE 600 |

| Paper width [mm] | 350 | 450 | 550 | 620 |

| Print width [mm] | 330 | 430 | 530 | 600 |

| No. print. units[n] | 2-10 | 2-10 | 2-10 | 2-10 |

| Unwinding diameter [mm] | 1000 | 1000 | 1000 | 1000 |

| Max speed [m/min] | 220 | 220 | 220 | 220 |

| Min print length [inches] | 8 | 8 | 8 | 8 |

| Max print length [inches] | 24 | 24 | 24 | 24 |

| Min length rotary die [inches] | 8 | 8 | 8 | 8 |

| Max length rotary die [inches] | 24 | 24 | 24 | 24 |

| No. rotary dies [n] | 2-5 | 2-5 | 2-5 | 2-5 |

| Printable materials | paper, adhesive paper, extensible film | paper, adhesive paper, extensible film | paper, adhesive paper, extensible film | paper, adhesive paper, extensible film |

Find a dealer

Select a zone to view dealers:

Request for information

Contact us for any information or to request a quote for this product.